Optimising predicting and designing new catalysts

Led by Professor Richard Catlow

The initial projects include:

-

Future developments in catalysis using synchrotrons;

-

Novel applications of neutron scattering in catalysis;

-

Future developments in catalysis using lasers;

-

New areas and opportunities for catalysis;

-

Integrating catalysis through cascade processes;

-

Modelling in catalytic science;

-

Changing the philosophy of catalysis design.

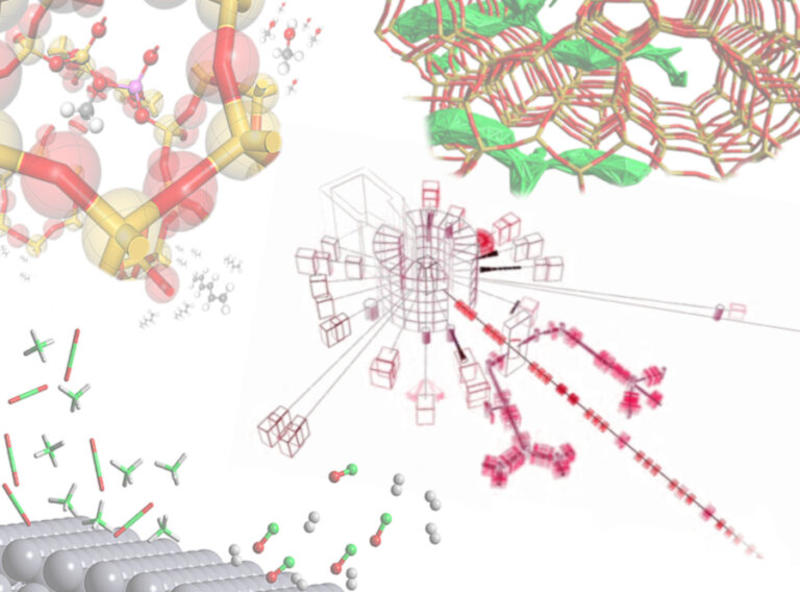

Understanding of catalysts and catalytic processes at the molecular level is vital for optimising existing catalytic processes and developing and designing new systems. This theme built on phase 1 of the UK Catalysis Hub with a powerful combination of technique development around the world class facilities on the campus and with adventurous applications embracing the full range of catalytic science, computational studies and engineering. This created a world leading programme of catalytic science and engineering, exploiting to the full the unique opportunities opened up in development of synchrotron, neutron and laser science.

image credit: Alex O'Malley

WP1: Future developments in catalysis using synchrotrons (Lead – Wells (Southampton), Gibson (Glasgow))

The UK Catalysis Hub spearheaded the use of in situ methodologies at the Diamond Light Source in its initial period. A number of key examples of ground breaking catalysis science have been published to date. This project explored the use of synchrotron facilities in the advancement of catalyst studies and used further improvements in methodology to design new catalysts for key chemical transformations.

WP2: Novel applications of neutron scattering to catalysis (Lead – Lennon (Glasgow))

This project used instruments at the ISIS Pulsed Neutron and Muon Facility e.g. NIMROD, TOSCA, OSIRIS to study of catalysts and catalytic systems. Specifically, they enabled time resolved studies to become feasible. Johnson Matthey, a UK based company that is a major supplier of catalysts and catalytic solutions collaborated with all WP2 developments.

WP3: Future developments in Catalysis using lasers (Lead – Beale (UCL), McGregor (Sheffield)

Spectroscopic methods offer an often unique way to interrogate catalysts under operating conditions. During the initial phase of the UK Catalysis Hub we made some initial use of the Central Laser Facility (CLF) at Harwell. This project explored the facility further.

WP4: New areas and opportunities for Catalysis (Lead – Davis (Oxford), Hutchings (Cardiff)

Catalysis underpins much modern life but our academic and intellectual study of the area has traditionally focused on modes of catalysis that ‘make things’ and indeed these traditional focuses have correctly dominated the first 5 themes of the Catalysis Hub. However, application of the deep understanding gained in these traditional themes into vital translational areas has the potential to re-think the design of catalysis as it currently sits in un-considered areas. We have identified two vital translational applications of catalysis for which there is great opportunity for creative innovation: (i) Medicinal Catalysis and the (ii) Catalysis of Things.

WP5: Integrating catalysis through cascade processes (Lead – Weller (Oxford) Dyer (Durham))

One of the big remaining challenges in catalysis is the integration of several chemical reactions into a single process step, at least one of which requires a catalyst, so-called catalytic cascade processes. Here, the product of one reaction becomes the reactant for the next without the need for time-consuming isolation of intermediates, improving both process and atom efficiency, while streamlining reaction engineering. Thus, cascade reactions are efficient tools for the synthesis of both commodity compounds and complex molecular architectures. However, the cascade methodology does bring its own set of problems in that there are often differing combinations of reaction conditions required for each of the steps, which is particularly challenging when combining homo- and hetero-geneous catalysis.

WP 6: Modelling in Catalytic Science (Lead – Mulholland (Bristol), Catlow (Cardiff))

Computer modelling is an essential component of catalytic science. Computation plays a vital role in developing models of catalysis at the molecular level, and in linking mechanistic understanding to macroscopic and systems-based kinetics models. Especially with techniques based on synchrotron radiation and neutron scattering. Hub science exploits the power of contemporary modelling techniques which will be even more strongly integrated with experiment and all applications areas. This project grew this approach especially in ‘interface’ applications e.g. in biocatalysis. Catalyst design and optimization, through synergistic interplay of simulation and experiment, were key. The Hub played a coordinating role in linking expertise in modelling in the wider computational catalytic community and facilitating exchange of developments in software and algorithms, via workshops at RCaH.

WP7: Changing the Philosophy of Catalyst Design (Lead – Blacker (Leeds), Gavriliidis (UCL), Hutchings (Cardiff)

The exploitation of catalytic methodologies in chemical manufacture requires from the outset the design of efficient processes that recognise the constraints and limitations that industry face. However, often in the initial stages of catalyst design the engineering and chemical catalysis components are disconnected and this leads to catalyst designs that often cannot be readily engineered into a final process. This project focussed on key reactions e.g. catalyst for high temperature oxidation, creating a methadology for integrating engineering into the catalysis design process.