RCAH Impact Fellows Report, Dr Simon Jacques, Manchester

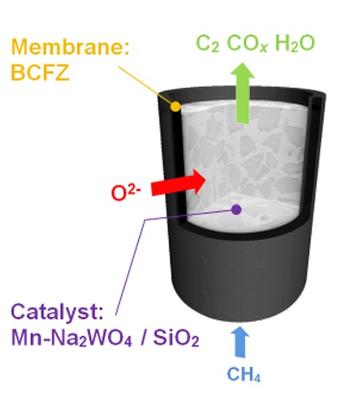

Figure 1 diagram of membrane reactor

image credit: Simon Jaques

The RCaH Advanced Impact Position is an EPSRC scheme that encourages collaborative research between groups based at the Research Complex Harwell. I have been fortunate enough to have been awarded one of these fellowships. My project is a collaboration principally with Manchester X-ray Imaging Facility and the UK catalysis hub with the aim of developing methods to image the changing chemistry within working catalytic membrane reactors. These are a new breed of catalytic reactors and we are using these for the efficient and clean conversion of methane to industrially useful feedstock materials such as ethylene. Below is summary of the project and the progress made to date.

The imperative for efficient technologies to process methane:

The continuous reduction of gas flaring and the exploitation of shale gas by hydraulic fracturing (fracking) has led to a dramatic increase in the availability of methane. Natural gas, whose main component is methane, is considered to be an abundant hydrocarbon source compared to crude oil and consequently there is much interest in producing higher value bulk chemicals from it. Environmentally-friendly and cost-effective processing technologies for direct conversion of methane to light olefins (e.g. ethylene) as an alternative to the highly energy-intensive cracking of crude oil are needed. The oxidative coupling of methane (OCM) can potentially provide an economically viable route for ethylene production. The application of catalytic membrane reactors (CMR) employing oxygen transport membranes can lead to a decrease of the cost of the overall process.

The reactor:

Figure 1, shows the principle of operation of such a reactor. The membrane facilitates the transport of oxygen ions from surrounding air atmosphere to feed the catalytic bed with oxygen. Methane is fed into the base of the reactor and is oxidatively coupled by virtue of an OCM catalyst to produce ethylene product. This process is highly advantageous in that it does not need a source of pure oxygen per se or require separation of product from contaminating gasses such as nitrogen.

Whilst this technology is very promising, there is little known about the workings of membrane and catalyst candidate materials in combination.

Chemical Imaging:

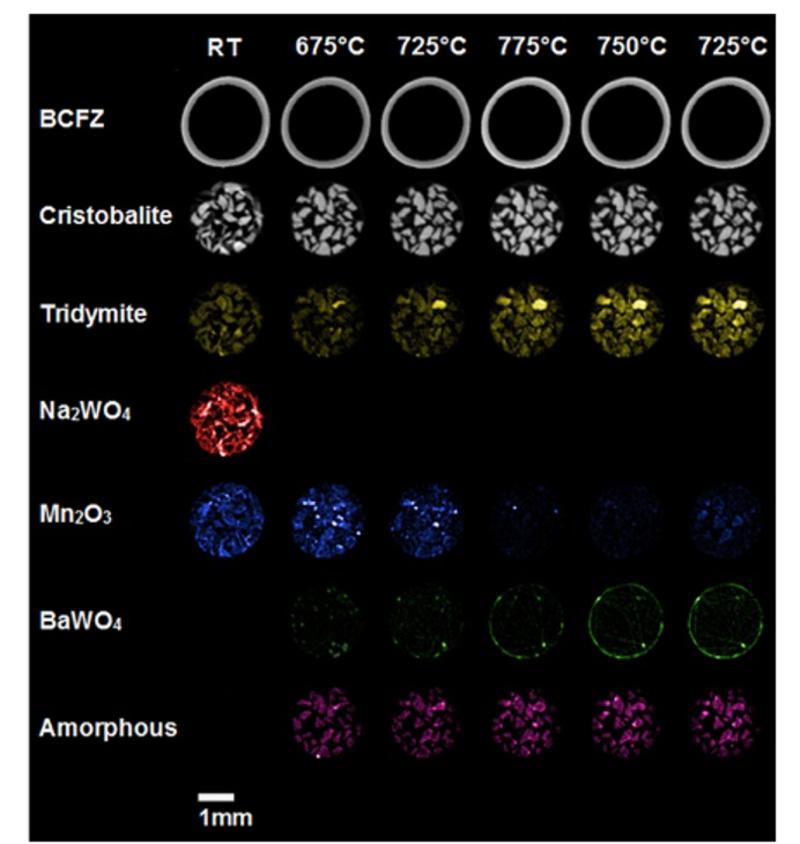

We have been developing a number of chemical imaging methods including X-ray diffraction computing tomography (XRD-CT) which we have used to image working CMR under operando conditions. XRD-CT is extremely powerful as it enables one to obtain images from bulk objects, where the composing pixels contain reconstructed diffraction patterns that themselves contain highly insightful physico-chemical information. Figure 2 below shows XRD-CT derived phase maps at a fixed height within a CMR under different applied conditions. The maps show that the position of the BCFZ membrane (BaCo0.4Fe0.4Zr0.2O3-δ), and the catalyst distribution within the catalyst particles within the hollow of the membrane, including the catalyst support phases (cristobalite, tridymite) and catalyst phases (Na2WO4 & Mn2O3) as a function of operating temperature. In this experiment we also see the evolution of BaWO4 which is resulting from the interaction of the catalyst with the membrane. The formation of this phase is highly likely to be detrimental to the long term operation of the CMR. This phase would likely be unobservable by conventional single point measurements.

Phase maps for BCFZ, cristobalite and tridymite (SiO2 polymorphs), Na2WO4, Mn2O3, Ba2WO4 and an amorphous phase as determined from the XRD-CT data. These maps have been obtained from the integrated intensities of the respective phases.

Current state of project:

We are using XRD-CT and supporting measurements to look at a number of membrane catalyst combinations under intended industrial operating conditions. We have recently published a short paper reporting some initial findings and also a methods based paper [2] detailing some developed methods. We are currently preparing full papers on the membrane/catalyst combinations studied to date and also a second methods paper.

figure 2 image of xrd ct derived phase maps

image credit: Simon Jaques

References:

[1] Real time chemical imaging of a working catalytic membrane reactor during oxidative coupling of methane. Vamvakeros, A., Jacques, S. D. M., Middelkoop, V., Di Michiel, M., Egan, C. K., Ismagilov, I. Z., Vaughan, G. B. M., Gallucci, F., van Sint Annaland, M., Shearing, P. R., Cernik, R. J. & Beale, A. M. (2015). Chem. Commun. 51, 12752-12755. http://pubs.rsc.org/en/Content/ArticleLanding/2015/CC/c5cc03208c#!divAbstract

[2] Removing multiple outliers and single crystal artefacts from X-ray diffraction computed tomography data. Vamvakeros, A., Jacques, S. D. M., Middelkoop, V., Di Michiel, M., Egan, C.K., Cernik, R. J. & Beale, A. M. (2015). Accepted J. Appl. Cryst. https://doi.org/10.1107/S1600576715020701