Catalysis facilities at Harwell Campus

The physical hub in the RCaH has been crucial to the success of the whole Hub project. It has provided first class facilities for research in catalytic science, which are a resource for the whole community. The laboratories have been used effectively by visiting scientists and the Hub team at Harwell including those undertaking experimental work on the central facilities, while promoting fruitful interactions other groups in the RCAH and the Harwell campus more broadly.

Custom catalysis labs

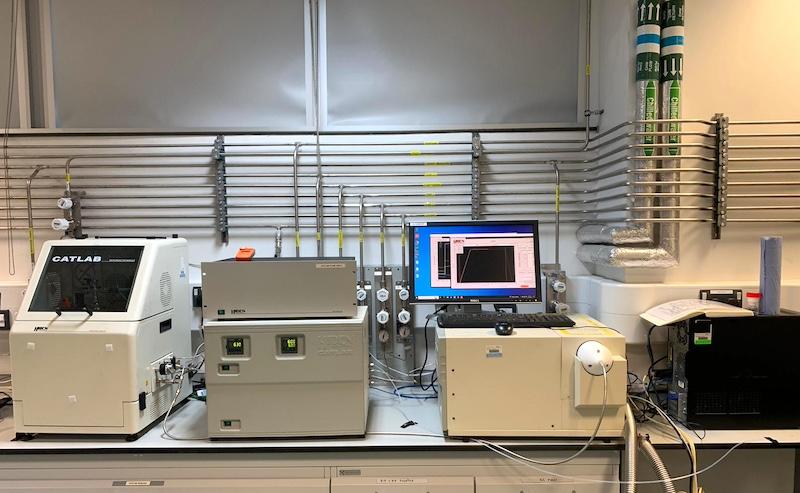

The UK Catalysis Hub has developed custom catalysis labs and analysis at the RCAH including a gas handling laboratory and provided the bespoke catalysis instrumentation (EPSRC Grant EP/K005030/1). The ring-main system has eight lines for different specialty gases, with each gas having ten individually regulated drop-off points around the laboratory.

The catalysis equipment currently available includes:(i) rapid scanning FT-IR with combined XAFS/ DRIFTS capabilities with Custom designed Portable gas handling system, (ii) a suite of autoclave reactors, (iii) a multi-tubular reactor assembly for heterogeneous catalysis studies, (iv) a flow reactor for homogeneous catalysis, (v) a Hiden CATlab for heterogeneous catalysis studies, TPO, TPD and TPR, (vi) a suite of high performance liquid and gas chromatographs and (vii) a microwave-plasma atomic emission spectrometer, (viii) Quantocrome four station BET surface area analyser and vii) Quantchrom ChemBET TPO/TPD analyster.

In addition to the gas handling lab the Catalysis team also occupy a lab for preparative chemistry work, which has also been aided by the transfer of the necessary equipment for preparing and handling air and moisture sensitive compounds (Schlenk line, vacuum pumps etc.). The catalysis team currently has office space sufficient for 20 desks and 158 m2 of laboratory space.

For information about using the UK Catalysis Hub labs and equipment, please contact the Laboratory Manager - Oliver Hodson. His working hours are 9 - 5PM, Monday - Wednesday.

UK Catalysis Hub Equipment List

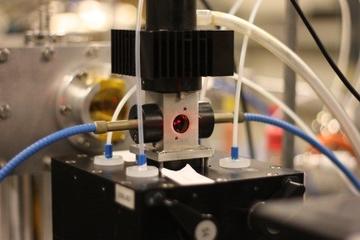

a. DRIFTS Setup

Diffuse Reflectance Infrared Fourier Transform Spectroscopy is an infrared technique ideal for research on catalyst surfaces. It allows the chemical and structural evaluation of all types of solid surfaces (including non-transparent, highly absorbing materials, coatings and roughened surfaces). An infrared beam focused onto a fine particulate material can interact with it in several possible ways. It can be absorbed, reflected from the surface or penetrate the particles before being scattered. Diffuse reflectance results from the penetration of the incident radiation into one or more particles and subsequent scattering from the sample matrix. The advantages of DRIFTS over conventional FTIR methods include the following: (i) DRIFTS is fast and non-destructive since the sample can be analysed as is or in powdered form, (ii) It is well suited to the analysis of strongly absorbing materials which are characterized by very low signals and sloping baselines when investigated in transmission mode, (iii) It requires little or no sample preparation.

The transmission cell (Harrick cell) allows for transmission-mode measurements of solid samples at between -196°C – 350°C in a controlled environment and is ideal for the investigation of catalytic and other solid-gas chemical reactions. The cell is made from 316 stainless steel, with a Dewar incorporated into the accessory for low temperature operation. Gases can be flown through the cell and it can be used with vacuum down to 10-6 Torr. It is equipped with low voltage heaters for heating the sample. The cell can also be reconfigured for near-normal (12°) specular reflection with a Variable Angle Reflection Accessory. d. Gas Cell

This is a temperature-controlled cell which can be used for both static and flow applications. It is made of stainless steel, is thermally isolated and has a path length of 10 cm. The maximum operable temperature of the cell is defined by the o-ring material. O-rings available with us include Kalrez (Temperature limit 260°C) and viton (Temperature limit 260°C). e. Linkam Cell

The Linkam Cell is designed to study catalytic reactions at high temperature and pressure. The cell works in reflectance mode. The samples are mounted on ceramic fabric filters placed inside a ceramic heating element, capable of heating samples from room temperature up to 1000°C very quickly, up to 5 bar pressure. The stage body is water cooled to keep it at safe temperature. The cell can be used with a variety of gases, including corrosive gases. Lid windows made of several different materials can be used to adapt the cell to brightfield and Raman microscopy techniques as well. f. Agilent MP-AES The Agilent MP-AES 4100 is a benchtop microwave plasma atomic emission spectrometer based on a robust magnetically excited microwave plasma excitation source. It is used for simultaneous multi-analyte determination of major and minor metal. MPAES employs microwave energy to produce a plasma discharge, which eliminates the need for sourcing gases in remote locations. Atomized sample passes through the plasma, promoting the electrons to excited state. Light emission from the electrons is directed to a wide range, low noise CCD detector, measuring the intensity of each emission line and background simultaneously while providing excellent detection limits and precision. The instrument in the Catalysis Hub is set up to run inorganic and organic samples with general detection limits between ~100 ppb – 10%, depending on element. Along with the MP-AES, an Anton Paar Multiwave 3000 is available for digestion of solid samples. Generally, samples are digested using Aqua Regia at temperatures and pressures up to 310°C and 115 bar.

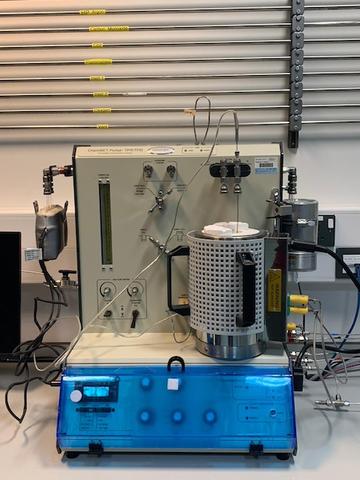

a. Parr Flow Reactors

The CATLAB system is a modular benchtop analysis system for comprehensive in-situ catalyst characterization, kinetic and thermodynamic measurements. The system is designed for both isothermal and temperature programmed studies of catalytic systems. The system consists of (i) a CATLAB microreactor module, which is a fast response, low thermal mass furnace, and (ii) a Hiden Analytical QIC-20 dynamic sampling mass spectrometer, which is a compact benchtop gas analysis system for continuous analysis of gases and processes at pressures up to atmosphere. The CATLAB uses Gas Adsorption Chromatography to directly determine metal surface areas for metals. It also allows the determination of surface coverages as a function of temperature and calculate the resulting adsorption isotherms. It can also be used to study energetics, kinetics and reaction mechanisms of catalytic systems using temperature programmed techniques up to 1000°C. The system has an integrated pulse valve to allow pulsed chemisorption studies, 8 flow channels with varied flows between 3 – 500 ml/min and is suitable for use with corrosive gases.

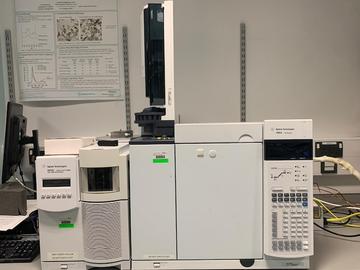

a. Gas Chromatography

High pressure Xe arc lamps make excellent artificial sources to simulate sunlight. The high colour temperature of the xenon lamps (6050 to 6350 K) is a close match to the solar temperature. This results in similar spectra in the UV and VIS although the lamp has some Xe emission lines in the near IR. Our LOT Quantum Design solar simulator is a 150W Xe light source. It includes filters to filter the Xe lamp to match various atmospheric conditions and thus match well with standard spectra. The matching is better in the UV and VIS than in the IR.

This is an intelligent potentiometric titrator and synthesis controller. Our titrator setup consists of a Metrohm 902 Titrando, a “dosino” dosing unit, a magnetic stirrer with base plate, and is controlled by a Tiamo 2.3 software interface.

This is a cost-effective reactor for gas-liquid reactions, offering the possibility to control reaction temperature and feed in gas with the same coil tube reactor. Liquid is fed through the coil and gas is fed through a separate connection at the desired pressure from a regulated supply. The reactor can be used in two different ways: Pre-dissolving the gas into the liquid before the reaction Performing the reaction in the reactor itself by feeding in the gas as it is consumed by the reaction.

BAG

Working as a collective unit at RCaH has enabled the catalysis team to gain programme access to the core XAFS beamline, B18, at Diamond Light Source (DLS), which provides the team with 24 shifts (8 days) of access per allocation period. This access route increases the efficiency of data acquisition by coordinating projects to reduce the dead time of experimental set-up and by allocating small amounts of time for proof of concept investigations before a full study starts.

In 2024 we announced a new call for a Quasi-Elastic Neutron Scattering (QENS) BAG at ISIS. We encourage users with no experience of QENS and will provide support throughout the process.

Find out about UK Catalysis Hub Block allocation access (BAG) calls on our BAG page.

Diamond Light Source and ISIS

The work of the Catalysis Hub at DLS has been mentioned in both the Diamond news magazine (summer 2013) and Diamond Podcast (Episode 24 – Catalysis). Moreover, the base at RCaH has also enabled the catalysis group to gain programme mode access to ISIS, which provides flexible access to the many beamlines available on both target stations. Sustained access to DLS and ISIS is essential in realising the synergistic benefits of the wide ranging facilities on the RAL campus.

Future facilities

Over the last five years we provided high throughput sample environments for both in situ and ex situ XAFS analysis, reactive gas environments for Quasielastic Neutron Scattering and an in situ spatially resolved plug flow reactor for neutron diffraction of liquid phase heterogeneously catalysed reactions with combined liquid phase composition analysis. We are currently working on high pressure and multi capillary reactors for in situ and operando experiments.

The development of The Catalysis Data Infrastructure and The Catalysis Research Workbench will enable further and easier exploitation of stored experimental data and assist in the characterisation or structure solution of catalytic compounds by integrating experimental and computational techniques.

Strategic Role of Location within RCaH

The RCaH is proving to be an ideal location for the Catalysis Centre for three main reasons:

- Catalysis is, as noted, a multidisciplinary science and the project is already profiting from interactions with other physical sciences programmes in the RCaH (especially the imaging project). Strong interactions with life sciences projects are anticipated in the future.

- The Centre is becoming a major user of synchrotron and neutron facilities and usage of laser facilities is anticipated. Our close proximity to the facilities is a major advantage in ensuring their effective exploitation.

- The location and ready access to the site and the fact that for university teams it is “neutral territory” has proved to be a major advantage in establishing the centre as the physical hub for the UK national catalysis programme.

More generally the Harwell/RAL campus is an increasingly strong base for an internationally leading collaborative scientific programme.

List of visitors to The Hub at Research Complex at Harwell.