When: 25 February, 15:00 GMT

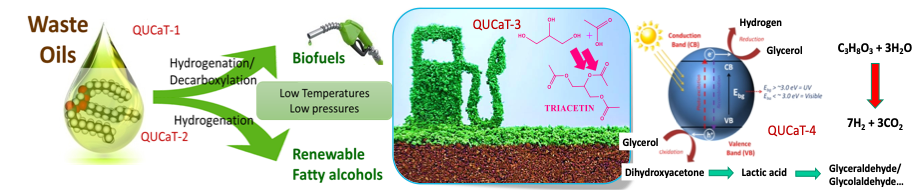

Increasing demand for materials and energy, coupled with more stringent curbs on greenhouse gas emissions and pollutants necessitates the urgent need for development of new improved and efficient chemical technologies for sustainable manufacturing of chemicals. In this context Catalysis is the most important technology to enable our transition to net zero carbon future, where the earth abundant metal oxide catalysts have a pivotal role from dynamic supports to active catalysts in energy efficient processes for chemicals and fuels. In this lecture we will visit some of the most recent developments in our research group including new design of metal oxide catalysts, reactors, and processes to reveal insights into the structure-activity relationships. Using key examples based on mechanochemical synthesis of more efficient catalysts, dual function materials, continuous flow platforms, 3D printed reactors, we will demonstrate the advances made in sustainable manufacturing to further achieve the ambitious 2050 net zero targets for Sustainable World. We continue to develop novel catalytic processes by combining catalyst design, process intensification, and in situ spectroscopy techniques with computational simulations. By using exemplar chemical processes such as hydrogenation, oxidation, alkylation, esterification, and ketonisation, we have established rational catalyst design criteria to engineer selectivity to desired products, improved process efficiency, catalyst stability and longevity. We have developed catalytic processes for sustainable production of a range of biofuels and platform chemicals including API processes for pharmaceutical industry, ingredients for perfumery and flavors industry, as well as fuels and fuel-additives such as gasoline and diesel range alkanes, bis-hydroxymethyl furfural, alkyl levulinates, GVL, glycerol triacetins, glycerol carbonate and renewable hydrogen production through photo-reforming.

Register for free at https://www.eventbrite.co.uk/e/why-robust-metal-oxide-catalysts-hold-the-key-to-sustainable-future-tickets-249285939957

View a recording of the webinar below:

Biography

Dr Haresh Manyar is Senior Lecturer in Chemical Engineering at Queen’s University Belfast, UK and adjunct Professor at Chandigarh University, India. His research focuses on the design and development of new catalysts and chemical processes in batch and continuous flow for sustainable chemical manufacturing and renewable energy. He has received several awards including the 2021 Innovation Award by SHV Energy, 2019 American Chemical Society’s I&ECR Excellence in review award, and 2016 Queen’s Teaching Award for excellence in Teaching. He has been promoting hands on learning experience for students based on Living lab concept using QUB campus infrastructure. He has received over £2 million in research grants from Royal Society, EPSRC, Leverhulme trust, Invest NI, STFC and chemical industry. He has several industrial collaborations including Almac Sciences, SHV Energy, Shell, Coryton advanced fuels, Johnson Matthey, Chevron, and Oleon. His research output includes over 130 papers/book chapters, patents/invention disclosures and conference proceedings with an h-index 22. He is the Fellow of Royal Society of Chemistry (FRSC), and Fellow of Higher Education Academy, UK (FHEA). He is Associate Editor of the Journal Frontiers in Chemical Engineering. He is appointed as an Expert by European Research Council on Individual Marie Curie Actions programme. He is a member of the UK Catalysis hub steering group, QUB Sustainable energy PRP, and research themes on Sustainability and Healthcare. He is also appointed to the Leadership forum of the IChemE Energy Centre Board. He has delivered numerous invited keynote and plenary talks worldwide.

Dr. Haresh Manyar

School of Chemistry and Chemical Engineering, Queen’s University Belfast, David-Keir Building, Stranmillis Road, Belfast BT9 5AG, UK.

Email: h.manyar@qub.ac.uk