Funding: UK Catalysis Hub, UCL, Diamond Light Source, Johnson Matthey

Aim

Building and commissioning of a high pressure (up to 3 bars) soft X-ray spectroscopy microreactor for industrial catalyst characterisation at the B07 beamline for identifying the nature of true active species during reaction.

Desired capabilities:

- Pressure up to 3 bars

- Temperature range 273 – 773 K

- Presence of gases (tox, flam)

- In-line products analysis (MS, GC)

- NEXAFS compatibility (TEY)

- Energy range 250 to 2800 eV

Background

It is well known from ex situ structural characterisation that the morphology, composition and crystalline structure of the catalysts evolve during catalytic reactions. Undoubtedly significant progress has been made in using in situ X-ray diffraction (XRD), hard X-ray spectroscopy and computed tomography studies. However, taking into account that the metal active site loading in the sample is often only a few percent, the measured signal mainly originates from the bulk volume and not from the surface where the reaction takes place. Thus, the main scientific challenge for identifying the nature of true active species during reaction is the ability to accurately determine the behaviour/structure of the surface or species at the surface under operating conditions.

In situ soft X-ray absorption spectroscopy (NEXAFS) is capable of providing such data. Further to the surface sensitivity, spectra recorded at the L-edge offer 3-5 times greater energy resolution compared to those recorded at the K-edge, resulting in sharper spectral features. Transitions at the L-edge (2p-3d) are dipole-allowed, providing spectra that are more intense and structured than those from the dipole forbidden K-edge (1s-3d transitions). As a consequence, L-edge XAS spectra are more sensitive to oxidation and spin-states.

Outcomes

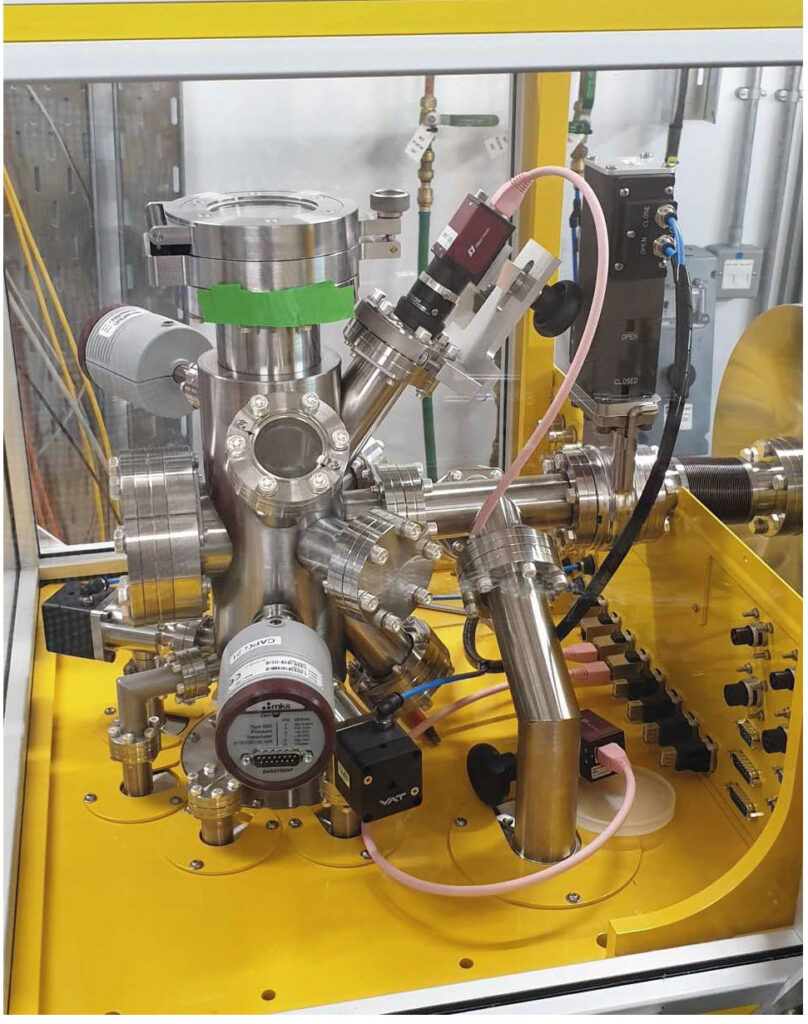

A new microreactor for the Ambient Pressure (AP) soft X-ray Absorption Spectroscopy (XAS) at the B07 VERSOX beamline at Diamond has been designed and commissioned. It has the volume of ~0.4 cm3 and be operational at pressure 1-3 bars in the temperature range 273 – 650 K. The microreactor was tested using hydrogen, CO, helium gases and their mixture.

The new cell was used to study effect of poisoning on the performance of Co-based catalyst with titania support during industrially important processes like Fischer-Tropsch (FT) synthesis, converting syngas to liquid fuels, above ambient pressure operating conditions. The observed degree of catalyst reduction for 7h at 650 K was considerably better in comparison to the previous work reporting in situ NEXAFS of similar system reduced at 2 mbar pressure for 12h at 700 K.

The new cell has extended the in situ capability available for NEXAFS analysis at Diamond from 20 mbar to 1-3 bar pressure. The proof of principle experiments have been successfully performed using industrial catalysts for waste to energy conversion. Setup is suitable not only for model 2D catalysts (previously reported in the literature for the same system) but also for industrially relevant powdered catalysts. New microreactor will become a part of the standard beamline equipment and will be available to the broader scientific community providing access to measurements of major importance that are currently unavailable in the UK.