When: 17 March 2021, 14:00 – 16:00 GMT

A joint virtual meeting between the Applied Catalysis Group (ACG) and UK Catalysis Hub based around the theme of applied characterization.

Speakers include:

Janelle Steves (GSK)

HTE in 3D

High-throughput Experimentation (HTE) offers the opportunity to explore expansive reaction space in a plate-based format. With the power to exponentially increase productivity compared to single reaction experiments, a chemist must judiciously choose which reaction parameters to evaluate in a HTE array. While this is not a completely empirical exercise, empiricism is often embedded in these designs in effort to span diverse reaction space. Our current workflow often stacks the deck with catalysts and reagents most likely to produce positive results based on literature data and our chemical intuition. Therefore, negative screening outcomes are often discarded upon analysis of results. Herein, we present an alternative analysis of HTE results from a Pd-catalyzed cross-coupling reaction using phosphine ligand steric and electronic descriptors obtained from quantum chemical calculations. This analysis models the trends in reactivity of the ligands across the entire series of positive and negative outcomes and provides insight into how phosphine ligand may influence reactivity and selectivity. Application of these steric and electronic descriptors to the design of new screening plates for Pd-catalyzed cross-coupling reactions will be discussed.

Biography:

After obtaining her Ph.D. at the University of Wisconsin-Madison and conducting postdoctoral work at Princeton University, Janelle joined GSK Chemical Development in October 2016. Over the past four years, she has developed processes for the pilot plant, expanded the Chemical Development HTE platform, and worked across scientific disciplines with computational chemists.

Watch a recording of the talk below:

David Lennon (Glasgow)

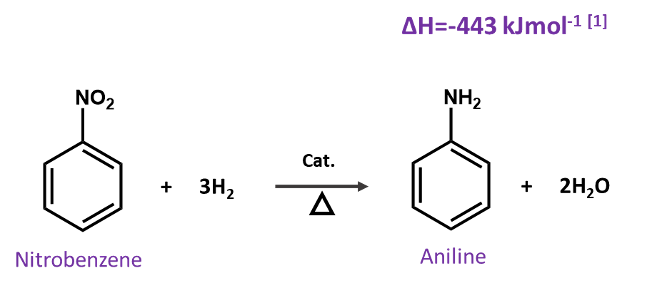

Towards developing structure/reactivity relationships for elevated temperature operation of ultra-selective aniline synthesis catalysts

The heterogeneously catalysed hydrogenation of nitrobenzene to synthesize aniline is a key reaction in the process chain to produce isocyanates, materials used in the production of polyurethanes. Reflecting the complexity of large-scale isocyanate manufacture, the reaction is typically undertaken within an integrated chemical complex [1]. This scenario then provides the opportunity to utilise the significant quantities of heat associated with the hydrogenation reaction (-443 kJ mol-1 !) to raise super-heated steam, which can then be employed as an energy vector within the particular chemical complex. This exercise in novel sustainable chemical manufacturing requires the hydrogenation reaction to be conducted at elevated temperatures, a condition that can compromise aniline selectivity.

This presentation will describe a collaboration with Huntsman Polyurethanes to develop structure/activity relationships for a series of alumina-supported palladium catalysts specified to deliver high aniline selectivity at elevated temperatures (T>100°C). Importantly, certain catalyst formulations were observed to favour different distributions of by-products, complicating exploitation of the intended step-change in industrial practice. Read more

Biography:

1985 University of East Anglia: B.Sc. (Hons) degree (first class) in Chemical Sciences

1989 University of East Anglia: Ph.D. in Chemical Physics (supervisor Professor Mike Chesters)

1990 University of Texas at Austin: Research Fellow (adsorbate photochemistry)

1992 University of Western Australia: Research Fellow (solid-state photochemistry)

1995 University of East Anglia: Research Fellow (solid state NMR; adsorbate photochemistry)

1996 University of Glasgow: ICI Lecturer in Heterogeneous Catalysis

2000 University of Glasgow: Senior Lecturer

2007 University of Glasgow: Reader

2015 University of Glasgow: Professor of Physical Chemistry

2016 University of Glasgow: Head of the Heterogeneous Catalysis Section.

Ben Deadman (ROAR)

Reaction Characterisation at The Centre for Rapid Online Analysis of Reactions (ROAR)

There are recognized deficiencies in the current pool of reaction data which are hindering the progress of synthetic chemistry towards becoming a predictive science. Over a century of synthesis has yielded a vast library of reactions but there is a pressing need for more comprehensive data sets which include negative results, multiple time-point reaction data, and interoperable synthesis procedures. The Centre for Rapid Online Analysis of Reaction (ROAR) is a new facility which brings together high-throughput (HT) batch and flow reactor platforms, in situ analytic technologies, and automation expertise to enable data-centric research in synthesis. In this talk we will demonstrate how ROAR can help characterise reactions using a case study of the catalytic reductive amination reaction.

Biography:

Ben is the facility manager of the Centre for Rapid Online Analysis of Reactions (ROAR). He uses his 12 years of experience in reaction automation and reaction analysis to support the facility users throughout their adventures in data-rich chemical synthesis experimentation.

Watch a recording of the talk below:

Paul Collier (JM)

Developing new characterisation capabilities in partnership with universities and the National Facilities

The characterisation of catalysts is of major importance in industry and leads to important knowledge about structure/activity relationships and thereby improved materials. This talk will look at the importance of characterisation in industry and of collaborations with universities and the National Facilities at Harwell, with two examples where collaboration has led to new characterisation capabilities.

Biography:

Dr Collier is a Research Fellow at Johnson Matthey and leads its research activities at Harwell and is also responsible for corporate analytical teams in NMR and XPS at the central research facility at Sonning Common. He has lead R&D teams looking at methane activation and MOF research along with diverse projects in catalysis and zeolite research. In addition to this he has lead a product development team based in the UK and USA looking at the scale-up and commercialisation to multi-tonne quantities of new catalysts. Dr Collier’s PhD was in precious metal nanocatalysis at Liverpool University and PDRA with Prof Hutchings at Cardiff University. With 20 years industrial experience and over 60 publications and patents Dr Collier has significant experience in science and technology in an applied setting.

Watch a recording of the talk below: