Over 10 gigatons of CO2 must be captured every year before 2050 if national and global net-zero pledges are to be met, the vast majority of which will likely be stored underground in geological rock formations. This means that CO2 is not only readily available and cheap, but it can also serve as a platform molecule to create the next generation of sustainable hydrocarbons.

Methanol (CH3OH) is a bulk chemical with huge industrial demand, as a precursor to fuels, plastic precursors, polymers and of course a solvent. There is growing interest in creating methanol by hydrogenating CO2, not just to fulfil global methanol demands, but also to act as an initial step in future multi-step processes, such as the potential to form longer chain hydrocarbons, directly from CO2 and green hydrogen.

Currently a significant amount of methanol is formed by reacting syngas (a mixture of CO2 and CO) with hydrogen over a Cu-ZnO-Al2O3 catalyst, typically in temperature between 200 and 300 oC, and up to 30 bar of pressure. However, this catalyst is not suitable for converting just CO2 and hydrogen to methanol, due to a limited lifetime and moderate selectivity to methanol. Because of this a variety of alternative catalysts, and alternative catalytic processes are being investigated within the European Research Council funded LAURELIN project. This project brings together ten different research partners from across the globe (https://alienor.eu/european-projects/laurelin/).

This project brought together experts in Non-Thermal Plasma catalysis (University of Manchester), Microwave technology (Fraunhofer) and Magnetic Induction processes (ITQ and CSIC). Each of these technologies had its own set of catalysts, and it was our role as the characterisation partner to understand the behaviour and activity of these catalysts under actual working (operando) conditions. Primarily this focussed on infra-red spectroscopy, but mainly on X-ray Adsorption Spectroscopy (XAS). In this work we worked closely with both Diamond Light Source (RAL, Harwell) and the European Synchrotron Research Facility (ESRF, Grenoble) staff to design and develop experiments that would allow us to observe changes in our material under these demanding conditions.

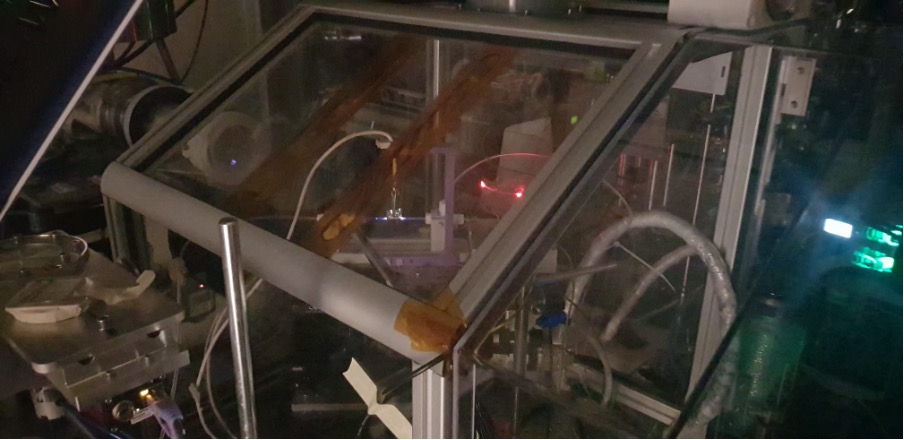

Figure 1: An operando XAS set-up for testing non-thermal plasma catalysts at the B18 beamline at Diamond Light Source with UCL and the University of Manchester.

While working at this project I was fortunate enough to be based at the UK Catalysis Hub. Not only did this make working with the Diamond community (just across the road) very easy, but having access to a wide range of in situ and operando techniques on a regular basis allowed us to complement our synchrotron findings with further experimental evidence. The time at the Hub allowed me to develop a wealth of new ideas and collaborators and is a community I am proud to continue being a member of in my new role.

Author: Dr. Matthew Potter

Previously: Research Fellow with Prof Andy Beale, UCL

Currently: Prize Fellow in Sustainable Chemical Technology, University of Bath (mep61@bath.ac.uk)