Chemical Transformations Theme highlights: Electrochemical characterisation and regeneration of sulfur poisoned Pt catalysts

The Energy theme of the UK Catalysis hub has undertaken a wide range of liquid and gas phase projects related to energy conversion catalytic technologies. ‘Electrochemical characterisation and regeneration of sulfur poisoned Pt catalysts’ was a project which attracted attention this year.

Catalytic hydrogenation processes are widely employed in the chemical industry for the synthesis of organic compounds. Typically, the catalysts in these processes consist of Pt and Pt-group nanoparticles supported on carbon. Additionally, sulfuric acid is frequently added, for operational reasons, to protonate the products and prevent product binding or over-reaction. However, it is found that the presence of sulfuric acid may lead to a poisoning of Pt catalysts, and it is unclear what species causes this effect, i.e. is it due to the presence of bisulfate, or due to sulfide owing to sulfuric acid reduction? Little is known about the sulfate/sulfide redox chemistry at Pt surfaces, nor is there a diagnostic measurement to identify and quantify the process. Electrochemistry is introduced in this project. Our work to date (in the first 6 months of this 12 month project) shows that it is a powerful tool to assess, characterize and regenerate catalysts due to sulfur poisons. The results provide a deep understanding of the poison of catalysts and offer ways for discovering new catalytical materials.

Various types of Pt materials, namely polycrystalline, single-crystal and Pt nanoparticles on a glassy carbon support have been studied. With electrochemistry, we are able to access and track the status of catalysts, e.g. cleanliness, surface area, surface structure. We have shown that many sulfur (S) compounds (NaHS, Na2SO3, SO2…) are poisons to platinum, greatly hindering the hydrogen adsorption reaction. More importantly, we show that all the poisoned Pt electrodes can be cleaned (regenerated) by voltammetric cycling. The regeneration kinetics are strongly related to the initial sulfur sources. Additionally, single-crystal studies allow decoupling of the effect of steps and terraces on platinum surfaces. Finally, XPS analysis has been employed, to elucidate the chemical state of sulfur species during the recovery process. This approach has significant importance in characterizing, selecting and regenerating platinum catalysts. The techniques and concepts can be transferred to study a wide range of catalysts materials. We believe it will offer new ways for understanding and discover new catalysts used in the industrial hydrogenation reactions.

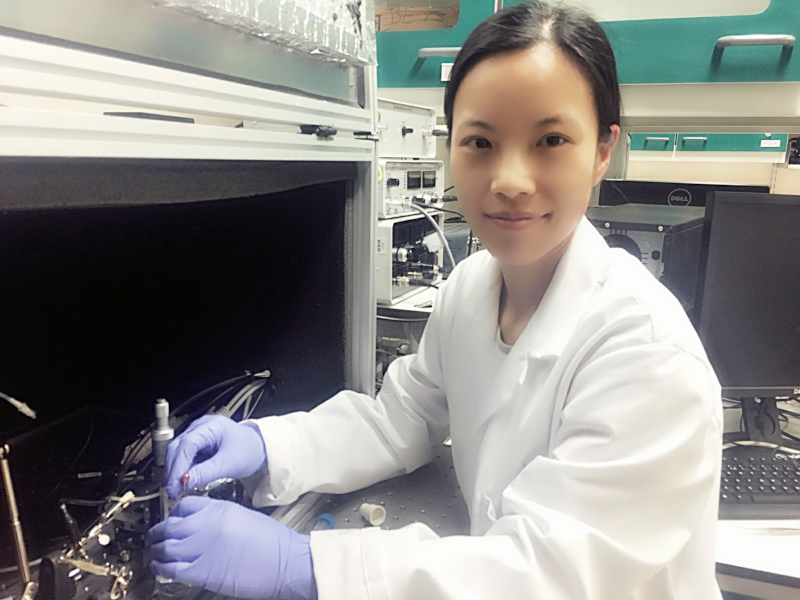

“Funding through the Catalysis Hub has enabled a multifaceted team to be assembled, comprising the groups of Paramaconi Rodriguez (Birmingham) and David Fermin (Bristol), working with the Warwick Electrochemistry & Interfaces Group and scientists at Syngenta. The postdoctoral research, Dr. Changhui Chen, has been central to co-ordinating activities and bringing her expertise in electrochemistry to bear. Her work has shown that electrochemistry is a powerful diagnostic tool to assess the status of platinum catalysts and to clean up contaminated catalyst surfaces. Ultimately, electrochemical methods could play an important role in heterogeneous catalysis to monitor the status of catalysts and clean them up in-situ.” ~ Professor Patrick Unwin

Author:

Dr Changhui Chen, Research Associate, Prof Patrick Unwin’s Group, The University of Warwick, Department of Chemistry

People involved:

University of Warwick, University of Birmingham, University Bristol, Syngenta Jealott’s Hill Research Centre