Development of an Ambient Pressure Microreactor for In Situ Soft XAS Analysis

In the new decade I have joined Finden Ltd after being an active Cat Hub member and UCL research fellow for four years. I now work as a Research Scientist at a spin-off company co-founded by Prof Andy Beale and based on the Harwell Campus, helping businesses and organisations across sectors to develop and improve their products by using advanced characterisation at the large scale facilities and data analysis.

Although my research at the Hub was focused on the application of surface-sensitive methods (NEXAFS/PEEM/GISAXS/SXRD/XPS) to better understand the nature of active sites in nanoparticulate catalysts under close to reaction conditions1, during the last two years my project was focused on building and commissioning of a high pressure (up to 3 bars) soft X-ray spectroscopy microreactor for industrial catalyst characterisation at the B07 beamline, DLS and was co-funded by the UK Catalysis Hub, Diamond and Johnson Matthey. In addition I was planning, training and supporting the conduct of research of visiting UK Cat Hub members at the national facilities i.e. Diamond and Research Complex at Harwell2 as well as co-supervising a PhD student studying metal-support interaction in the Fischer-Tropsch catalyst with the help of correlative microscopy3. Therefore over these years I have developed a wide range of relevant experiences both as user and to a large degree as local contact. This includes but not limited to XANES/EXAFS analysis at the B18 (BAG beamtime), NEXAFS at the B07, PEEM at the I06 and surface X-ray scattering at the I07 beamlines at the DLS and SEM, TEM, XRD, BET, ChemBET at the RCaH instruments as well as wet chemistry and catalyst testing labs.

The success of my multidisciplinary research project relied to a large degree on establishing and maintaining efficient and productive collaboration between UCL Chemistry Department, RCaH, Diamond Light Source and a number of external collaborators (JM, University of St Andrews, SLS and Soleil).

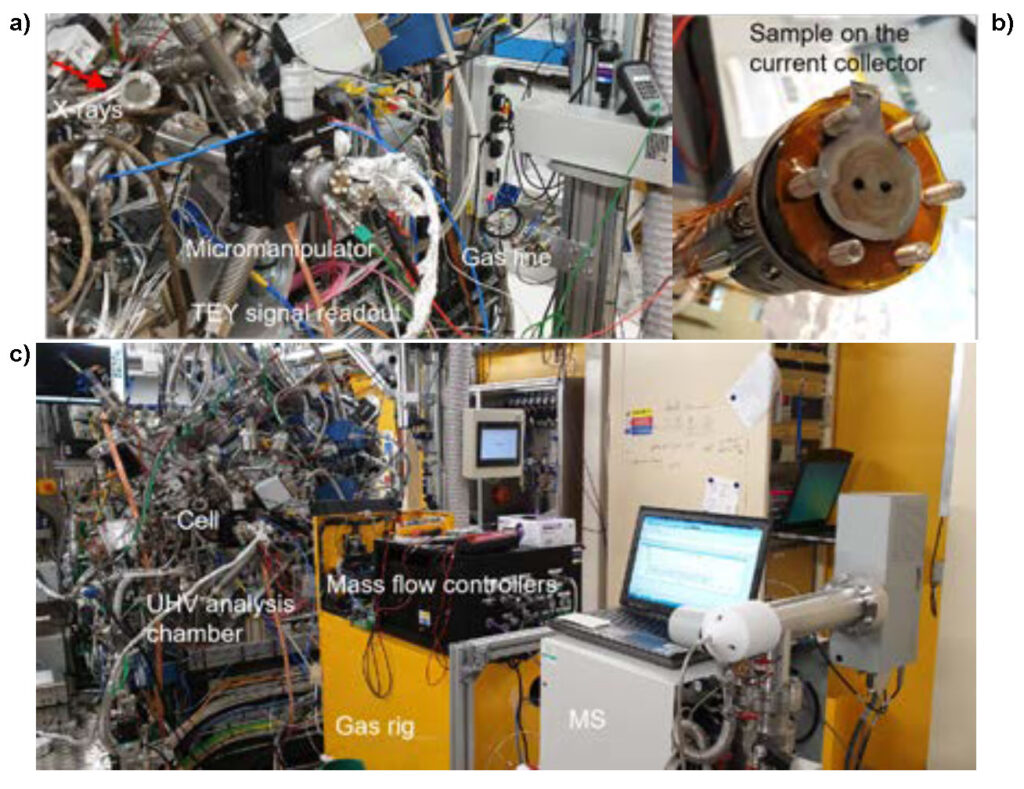

I really enjoyed working on the multidisciplinary project at the interface of physics, engineering and chemistry and interact with different people from academia and industry. It is well known from ex situ structural characterisation that the morphology, composition and crystalline structure of the catalysts evolve during catalytic reactions. Undoubtedly significant progress has been made in using in situ X-ray diffraction (XRD), hard X-ray spectroscopy and computed tomography studies. However, taking into account that the metal active site loading in the sample is often only a few percent, the measured signal mainly originates from the bulk volume and not from the surface where the reaction takes place. Thus, the main scientific challenge for identifying the nature of true active species during reaction is the ability to accurately determine the behaviour/structure of the surface or species at the surface under operating conditions. In situ soft X-ray absorption spectroscopy (NEXAFS) is capable of providing such data. Further to the surface sensitivity, spectra recorded at the L-edge offer 3-5 times greater energy resolution compared to those recorded at the K-edge, resulting in sharper spectral features. Transitions at the L-edge (2p-3d) are dipole-allowed, providing spectra that are more intense and structured than those from the dipole forbidden K-edge (1s-3d transitions). As a consequence, L-edge XAS spectra are more sensitive to oxidation and spin-states. Features attributable to adsorbed CO and bulk cobalt oxides were reported for O K-edge spectra in the literature. The new cell has extended the in situ capabilities available for NEXAFS analysis at Diamond from 20 mbar to 1-3 bar pressure. The proof of principle experiments have been successfully performed using industrial catalysts for waste to energy conversion (Fig. 1). Setup is suitable not only for model 2D catalysts (previously reported in the literature for the same system) but also for industrially relevant powdered catalysts. New microreactor will become a part of the standard beamline equipment and will be available to the broader scientific community providing access to measurements of major importance that are currently unavailable in the UK.

I will continue to interact with the Cat Hub (2 proposals where I am Co-PI have been accepted at I07 and B07 beamlines) and help developing better materials and technologies for our sustainable future.

References

Odarchenko, Y.; Martin, D. J.; Arnold, T.; Beale, A. M. CO Oxidation over Supported Gold Nanoparticles as Revealed by Operando Grazing Incidence X-Ray Scattering Analysis. Faraday Discuss. 2018, 208, 243-254.

Decarolis D.; Odarchenko Y.; Herbert J.J.; Longo A.; and Beale A. M. Identification of the Key Steps in the Self-Assembly of Homogeneous Gold Metal Nanoparticles. Physical Chemistry Chemical Physics (PCCP) 2019 (DOI: 10.1039/C9CP03473K)

Qiu C.; Odarchenko Y.; Meng Q.; Cong P.; Kleibert A.; Forrest T.; Beale A.M. Understanding the evolution of cobalt nanoparticles at the titania and silica interface, J. Phys. Chem. Lett. 2019.